Table of Contents

Advantages of Using Single Beam Hook Gantry Crane in Factories

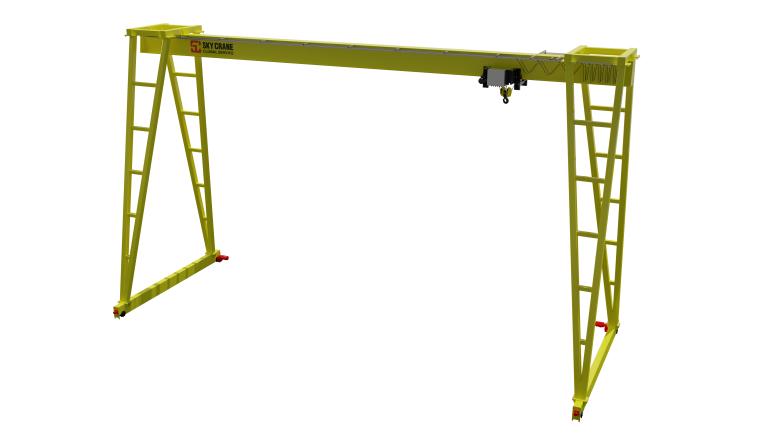

Single beam hook gantry cranes are a popular choice for factories looking to efficiently move heavy loads within their facilities. These cranes offer a number of advantages that make them a valuable asset in any industrial setting.

One of the key advantages of using a single beam hook gantry crane in a factory is its versatility. These cranes can be easily customized to meet the specific needs of a factory, whether it be in terms of load capacity, span length, or lifting height. This flexibility allows factories to maximize their efficiency and productivity by ensuring that the crane is perfectly suited to the tasks at hand.

In addition to their versatility, single beam hook gantry cranes are also known for their ease of installation and operation. These cranes can be quickly and easily set up, minimizing downtime and allowing factories to get up and running as soon as possible. Once installed, these cranes are simple to operate, with intuitive controls that make it easy for workers to safely and efficiently move loads around the factory floor.

Another advantage of using a single beam hook gantry crane in a factory is their cost-effectiveness. These cranes are typically more affordable than other types of lifting equipment, making them a budget-friendly option for factories looking to improve their material handling capabilities. Additionally, the low maintenance requirements of single beam hook gantry cranes help to keep operating costs down, further increasing their cost-effectiveness.

Safety is always a top priority in any industrial setting, and single beam hook gantry cranes are designed with safety in mind. These cranes are equipped with a range of safety features, such as overload protection systems and emergency stop buttons, to help prevent accidents and protect workers. Additionally, the sturdy construction of single beam hook gantry cranes ensures that they can safely lift and move heavy loads without compromising the safety of workers or damaging the crane itself.

| Number | Products |

| 1 | QD OVERHEAD CRANE WITH HOOK CAP.5-800/150T |

| 2 | Semi – gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

The compact design of single beam hook gantry cranes is another advantage that makes them well-suited for use in factories. These cranes take up minimal space on the factory floor, allowing for efficient use of space and maximizing the available working area. This compact design also makes single beam hook gantry cranes easy to maneuver around the factory, ensuring that they can reach even the most hard-to-reach areas.

In conclusion, single beam hook gantry cranes offer a range of advantages that make them an ideal choice for factories looking to improve their material handling capabilities. From their versatility and ease of installation to their cost-effectiveness and safety features, these cranes are a valuable asset in any industrial setting. With their compact design and efficient operation, single beam hook gantry cranes are sure to help factories increase their productivity and efficiency.

Safety Measures to Follow When Operating Single Beam Hook Gantry Crane in Factories

Single beam hook gantry cranes are commonly used in factories for lifting and moving heavy loads. These cranes are essential for improving efficiency and productivity in industrial settings. However, operating a single beam hook gantry crane requires careful attention to safety measures to prevent accidents and injuries.

One of the most important safety measures to follow when operating a single beam hook gantry crane is to ensure that the crane is properly maintained. Regular inspections should be conducted to check for any signs of wear and tear, such as cracks or corrosion. Any damaged components should be repaired or replaced immediately to prevent accidents.

It is also crucial to ensure that the crane is operated by trained and qualified personnel. Operators should be familiar with the crane’s controls and safety procedures to prevent accidents. Proper training should be provided to all crane operators to ensure that they are aware of the risks associated with operating the crane.

Another important safety measure to follow when operating a single beam hook gantry crane is to ensure that the load being lifted is within the crane’s capacity. Overloading the crane can cause it to tip over or collapse, leading to serious accidents. Operators should always check the weight of the load before lifting it to ensure that it does not exceed the crane’s capacity.

In addition, it is essential to ensure that the area around the crane is clear of obstacles and personnel when operating the crane. This will help prevent accidents and injuries caused by collisions or falling objects. Operators should also be aware of their surroundings and communicate with other workers to ensure that everyone is safe during crane operations.

Proper communication is key to ensuring safety when operating a single beam hook gantry crane. Operators should use hand signals or radios to communicate with other workers and coordinate movements during lifting operations. Clear communication can help prevent accidents and ensure that everyone is aware of the crane’s movements.

It is also important to follow all safety guidelines and procedures provided by the crane manufacturer. These guidelines are designed to ensure the safe operation of the crane and prevent accidents. Operators should familiarize themselves with these guidelines and follow them at all times to prevent injuries and damage to the crane.

In conclusion, safety is paramount when operating a single beam hook gantry crane in factories. By following these safety measures, operators can prevent accidents and injuries and ensure the efficient and safe operation of the crane. Proper maintenance, training, load capacity checks, clear communication, and adherence to safety guidelines are essential for safe crane operations. By prioritizing safety, factories can create a safe working environment for their employees and prevent accidents and injuries.