Table of Contents

Advantages of Single Beam Gantry Cranes in Industrial Applications

Single beam gantry cranes have emerged as a vital component in various industrial applications, particularly due to their unique design and operational efficiency. One of the primary advantages of these cranes is their ability to provide a cost-effective solution for lifting and transporting heavy loads. Unlike traditional overhead cranes, single beam gantry cranes require less structural support, which translates to lower installation costs and reduced space requirements. This makes them particularly appealing for facilities with limited overhead clearance or those looking to optimize their workspace.

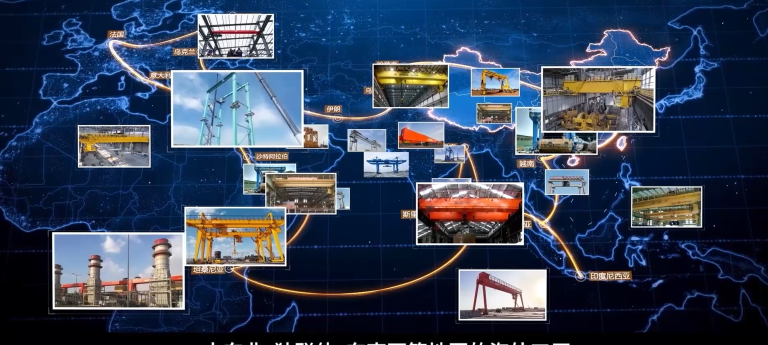

Moreover, the versatility of single beam gantry cranes cannot be overstated. They can be utilized in a wide range of environments, from manufacturing plants to construction sites, and even in shipping yards. Their adaptability allows them to handle various materials, including steel, concrete, and other heavy components, making them indispensable in industries such as construction, logistics, and manufacturing. Additionally, these cranes can be equipped with different types of hoists and attachments, further enhancing their functionality and enabling them to meet specific operational needs.

Another significant advantage of single beam gantry cranes is their ease of operation. Designed with user-friendly controls, these cranes can be operated by a single individual, which not only streamlines the lifting process but also minimizes the risk of accidents associated with multiple operators. Furthermore, the intuitive design of the controls allows for precise maneuvering, ensuring that loads are lifted and placed accurately. This precision is crucial in industrial settings where even minor miscalculations can lead to costly damages or safety hazards.

In terms of safety, single beam gantry cranes are equipped with various features that enhance their operational security. Many models come with overload protection systems, which prevent the crane from lifting loads that exceed its capacity. This feature is essential in preventing accidents and ensuring the safety of both the operators and the materials being handled. Additionally, the stability of single beam gantry cranes is enhanced by their low center of gravity, which reduces the risk of tipping during operation. This stability is particularly important in dynamic environments where conditions may change rapidly.

Furthermore, the maintenance requirements for single beam gantry cranes are relatively low compared to other lifting equipment. Their simple design means that fewer components are subject to wear and tear, which can lead to reduced downtime and lower maintenance costs. Regular inspections and basic upkeep are typically sufficient to keep these cranes in optimal working condition, allowing businesses to maximize their productivity without incurring significant additional expenses.

In conclusion, the advantages of single beam gantry cranes in industrial applications are manifold. Their cost-effectiveness, versatility, ease of operation, safety features, and low maintenance requirements make them an attractive choice for a wide range of industries. As businesses continue to seek efficient and reliable solutions for material handling, the demand for single beam gantry cranes is likely to grow. By investing in this type of equipment, companies can enhance their operational efficiency, improve safety standards, and ultimately contribute to their overall success in a competitive market. The continued evolution of these cranes, particularly from leading manufacturers, ensures that they will remain a cornerstone of industrial operations for years to come.

Key Features of Box Type Gantry Cranes from Chinese Manufacturers

Box type gantry cranes, particularly those manufactured by leading Chinese factories, have gained significant recognition in the global market due to their robust design and versatile applications. One of the key features of these cranes is their structural integrity, which is primarily attributed to the box-shaped design of the main girder. This design not only enhances the crane’s load-bearing capacity but also contributes to its stability during operation. The box type structure minimizes the risk of deformation under heavy loads, making it an ideal choice for industries that require reliable lifting solutions.

In addition to their structural advantages, box type gantry cranes are equipped with advanced technology that enhances their operational efficiency. Many Chinese manufacturers incorporate state-of-the-art control systems, which allow for precise maneuvering and positioning of loads. These systems often include features such as remote control operation and programmable logic controllers (PLCs), which streamline the lifting process and reduce the likelihood of human error. Consequently, operators can achieve higher productivity levels while ensuring safety standards are met.

| Serial Number | Commodity Name |

| 1 | QD OVERHEAD CRANE WITH HOOK CAP.5-800/150T |

| 2 | Universal gantry crane |

| 3 | European-style crane |

| 4 | Harbour crane |

Moreover, the versatility of box type gantry cranes is another significant feature that sets them apart from other lifting equipment. These cranes can be customized to suit various operational needs, including different lifting capacities, spans, and heights. This adaptability makes them suitable for a wide range of applications, from construction sites to shipping yards and manufacturing facilities. Furthermore, many Chinese manufacturers offer options for additional attachments, such as spreader beams and lifting hooks, which further enhance the crane’s functionality.

Another noteworthy aspect of box type gantry cranes is their ease of assembly and disassembly. Chinese manufacturers often design these cranes with modular components, allowing for quick setup and takedown. This feature is particularly beneficial for projects that require temporary lifting solutions or for companies that operate in multiple locations. The ability to transport and reassemble the crane with minimal effort not only saves time but also reduces operational costs.

Safety is a paramount concern in any lifting operation, and box type gantry cranes from Chinese manufacturers are designed with this in mind. Many models come equipped with safety features such as overload protection systems, emergency stop buttons, and limit switches. These safety mechanisms are crucial in preventing accidents and ensuring the well-being of operators and personnel in the vicinity. Additionally, regular maintenance and inspection protocols are often emphasized by manufacturers, further enhancing the safety and reliability of these cranes.

Furthermore, the cost-effectiveness of box type gantry cranes is an appealing feature for many businesses. Chinese manufacturers are known for providing high-quality equipment at competitive prices, making these cranes an attractive option for companies looking to optimize their lifting operations without exceeding budget constraints. The combination of affordability and durability ensures that businesses can achieve a favorable return on investment over time.

In conclusion, the key features of box type gantry cranes from Chinese manufacturers highlight their structural integrity, advanced technology, versatility, ease of assembly, safety measures, and cost-effectiveness. These attributes make them a preferred choice for various industries seeking reliable and efficient lifting solutions. As the demand for such equipment continues to grow, the innovations and improvements in design and functionality from Chinese manufacturers will likely play a pivotal role in shaping the future of material handling.

Comparing Cost-Effectiveness of Chinese Best Factory Gantry Cranes

When considering the acquisition of a gantry crane, particularly the single beam gantry crane box type from Chinese Best Factory, it is essential to evaluate its cost-effectiveness in relation to its performance and longevity. The initial investment in such equipment can be substantial, but understanding the long-term benefits and savings can provide a clearer picture of its overall value. Chinese Best Factory has established a reputation for producing high-quality gantry cranes that are not only competitively priced but also designed to meet rigorous industrial standards.

One of the primary factors contributing to the cost-effectiveness of these gantry cranes is their robust construction. The box-type design enhances structural integrity, allowing for greater load capacity while minimizing the risk of deformation or failure under heavy loads. This durability translates into lower maintenance costs over time, as the need for frequent repairs or replacements is significantly reduced. Furthermore, the materials used in manufacturing these cranes are selected for their strength and resistance to wear, ensuring that the equipment remains operational for many years, thereby maximizing the return on investment.

In addition to durability, the efficiency of operation plays a crucial role in determining the cost-effectiveness of gantry cranes. The single beam design allows for smooth and precise movements, which can enhance productivity in various applications, from construction sites to warehouses. By facilitating faster loading and unloading processes, these cranes can help businesses reduce labor costs and improve overall operational efficiency. Consequently, the initial expenditure on a gantry crane can be offset by the increased productivity and reduced operational costs that it brings.

Moreover, Chinese Best Factory offers a range of customization options, allowing businesses to tailor the gantry crane to their specific needs. This flexibility can lead to further cost savings, as companies can invest in features that directly address their operational requirements without incurring unnecessary expenses on superfluous capabilities. For instance, integrating advanced control systems or safety features can enhance operational efficiency and worker safety, ultimately contributing to a more cost-effective solution.

Another aspect to consider is the availability of spare parts and after-sales support. Chinese Best Factory is known for its commitment to customer service, providing readily available spare parts and technical assistance. This accessibility ensures that any downtime due to maintenance or repairs is minimized, which is critical for maintaining productivity levels. The ability to quickly source parts and receive expert support can significantly reduce the total cost of ownership, making the gantry crane a more attractive investment.

Furthermore, the competitive pricing of Chinese Best Factory gantry cranes is a significant advantage in the global market. By leveraging advanced manufacturing techniques and economies of scale, the factory can offer high-quality cranes at prices that are often lower than those of competitors. This affordability does not compromise quality; rather, it reflects the factory’s commitment to providing value to its customers.

In conclusion, the cost-effectiveness of single beam gantry cranes from Chinese Best Factory is evident when considering their durability, operational efficiency, customization options, and strong after-sales support. By investing in such equipment, businesses can achieve significant long-term savings while enhancing productivity and safety. Ultimately, the decision to choose a gantry crane from this reputable manufacturer can lead to a favorable return on investment, making it a wise choice for companies looking to optimize their operations.