Table of Contents

Benefits of Using CD1/MD1 Electric Hoists in Industrial Applications

Electric hoists are essential tools in various industrial applications, providing a safe and efficient way to lift and move heavy loads. Among the many options available in the market, CD1/MD1 electric hoists stand out as some of the best choices for manufacturers in China. These hoists are known for their reliability, durability, and high performance, making them a popular choice for a wide range of industries.

One of the key benefits of using CD1/MD1 electric hoists is their versatility. These hoists are designed to handle a wide range of loads, from light to heavy, making them suitable for various industrial applications. Whether you need to lift small components in a workshop or move heavy machinery in a manufacturing plant, CD1/MD1 electric hoists can get the job done efficiently and safely.

In addition to their versatility, CD1/MD1 electric hoists are also known for their durability. These hoists are built to withstand the rigors of daily use in industrial settings, ensuring that they can perform reliably for years to come. With proper maintenance and care, CD1/MD1 electric hoists can provide a long service life, making them a cost-effective investment for manufacturers in China.

Another advantage of using CD1/MD1 electric hoists is their high performance. These hoists are equipped with powerful motors and precision-engineered components, allowing them to lift heavy loads with ease. Whether you need to lift a few hundred kilograms or several tons, CD1/MD1 electric hoists can handle the task efficiently and safely, helping to improve productivity and streamline operations in your facility.

Safety is a top priority in any industrial setting, and CD1/MD1 electric hoists are designed with this in mind. These hoists are equipped with a range of safety features, such as overload protection, emergency stop buttons, and limit switches, to ensure that operators can work safely and confidently. By using CD1/MD1 electric hoists, manufacturers in China can create a safer working environment for their employees and reduce the risk of accidents and injuries.

In addition to their performance and safety features, CD1/MD1 electric hoists are also easy to operate and maintain. These hoists are designed with user-friendly controls and intuitive interfaces, making them easy for operators to use. With regular maintenance and inspections, CD1/MD1 electric hoists can continue to perform at their best, helping manufacturers in China to maximize their efficiency and productivity.

Overall, CD1/MD1 electric hoists are an excellent choice for manufacturers in China looking for reliable, durable, and high-performance lifting solutions. With their versatility, durability, performance, safety features, and ease of operation, CD1/MD1 electric hoists can help manufacturers streamline their operations, improve productivity, and create a safer working environment for their employees. If you are in the market for a new electric hoist for your industrial facility, consider choosing CD1/MD1 electric hoists from China’s best manufacturer.

Features to Look for When Choosing a CD1/MD1 Electric Hoist

When it comes to choosing an electric hoist for your lifting needs, there are several factors to consider to ensure you are getting the best product for your specific requirements. CD1/MD1 electric hoists are popular choices for many industries due to their versatility and reliability. In this article, we will discuss some key features to look for when selecting a CD1/MD1 electric hoist from a reputable manufacturer in China.

One of the most important features to consider when choosing a CD1/MD1 electric hoist is the lifting capacity. Different models of electric hoists have varying weight capacities, so it is crucial to determine the maximum weight you will need to lift in order to select the appropriate hoist for your needs. It is always recommended to choose a hoist with a higher lifting capacity than you anticipate needing to ensure safety and efficiency in your lifting operations.

Another important feature to consider is the lifting speed of the electric hoist. The lifting speed will determine how quickly you can move materials or equipment vertically, which can impact productivity and efficiency in your operations. It is important to choose a hoist with a lifting speed that is suitable for your specific lifting requirements.

In addition to lifting capacity and speed, it is essential to consider the durability and reliability of the electric hoist. Look for a hoist that is made from high-quality materials and has a robust construction to ensure it can withstand heavy use and harsh working conditions. A reliable hoist will help prevent downtime and costly repairs, ultimately saving you time and money in the long run.

Safety features are also crucial when selecting a CD1/MD1 electric hoist. Look for hoists that are equipped with safety mechanisms such as overload protection, emergency stop buttons, and limit switches to ensure the safety of operators and prevent accidents in the workplace. Safety should always be a top priority when choosing any type of lifting equipment.

Ease of maintenance and serviceability are additional factors to consider when selecting a CD1/MD1 electric hoist. Choose a hoist that is easy to maintain and service, with accessible components and clear maintenance instructions. Regular maintenance is essential to ensure the longevity and performance of your electric hoist, so choose a hoist that is user-friendly in terms of maintenance and serviceability.

Finally, consider the reputation and experience of the manufacturer when choosing a CD1/MD1 electric hoist. Look for a manufacturer with a proven track record of producing high-quality, reliable hoists that meet industry standards and regulations. A reputable manufacturer will provide excellent customer support and after-sales service, ensuring you have a positive experience with your electric hoist.

In conclusion, when choosing a CD1/MD1 electric hoist from a manufacturer in China, consider factors such as lifting capacity, speed, durability, safety features, maintenance, and the reputation of the manufacturer. By carefully evaluating these features, you can select the best electric hoist for your lifting needs and ensure safe and efficient operations in your workplace.

How to Properly Maintain and Service CD1/MD1 Electric Hoists

CD1/MD1 electric hoists are essential tools in various industries for lifting and moving heavy loads. To ensure the safety and efficiency of these hoists, proper maintenance and servicing are crucial. In this article, we will discuss the importance of maintaining CD1/MD1 electric hoists and provide some tips on how to properly service them.

Regular maintenance of CD1/MD1 electric hoists is essential to prevent breakdowns and ensure their longevity. By following a maintenance schedule, you can identify and address any potential issues before they escalate into major problems. This will not only save you time and money but also help prevent accidents and injuries in the workplace.

One of the most important aspects of maintaining CD1/MD1 electric hoists is lubrication. Proper lubrication of the hoist’s moving parts will reduce friction and wear, prolonging the hoist’s lifespan. It is recommended to use high-quality lubricants and follow the manufacturer’s guidelines for lubrication intervals.

| Number | Product Name |

| 1 | QD OVERHEAD CRANE WITH HOOK CAP.5-800/150T |

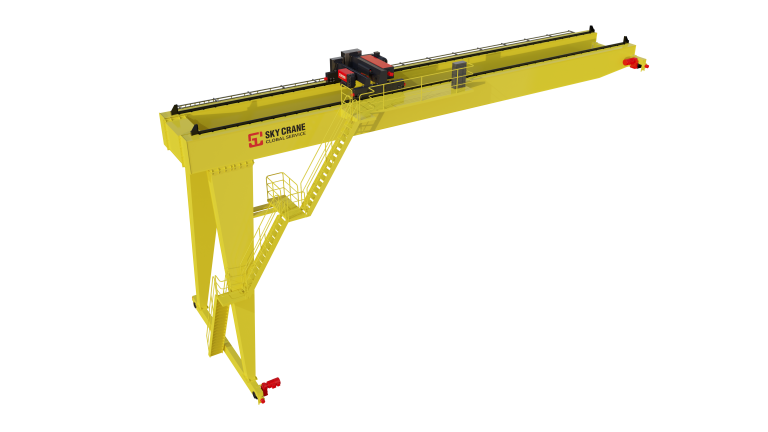

| 2 | Rubber – tired Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

In addition to lubrication, regular inspections are also crucial for the proper maintenance of CD1/MD1 electric hoists. Inspecting the hoist for any signs of wear and tear, loose bolts, or damaged components can help prevent accidents and ensure the hoist’s safe operation. It is recommended to perform inspections before each use and to keep a record of any maintenance or repairs done.

Another important aspect of maintaining CD1/MD1 electric hoists is cleaning. Keeping the hoist clean and free of debris will prevent contamination of the lubricant and reduce the risk of corrosion. It is important to use the appropriate cleaning agents and methods to avoid damaging the hoist’s components.

In addition to regular maintenance, servicing CD1/MD1 electric hoists is also essential to ensure their proper functioning. Servicing should be done by qualified technicians who are familiar with the hoist’s operation and maintenance requirements. It is recommended to have the hoist serviced at least once a year or more frequently if it is used frequently or in harsh environments.

During servicing, technicians will inspect the hoist for any signs of wear and tear, replace any worn or damaged parts, and perform any necessary adjustments. They will also test the hoist’s operation to ensure it meets safety standards and functions properly. It is important to follow the manufacturer’s guidelines for servicing and to use only genuine replacement parts.

In conclusion, proper maintenance and servicing of CD1/MD1 electric hoists are essential to ensure their safety and efficiency. By following a regular maintenance schedule, lubricating the hoist’s moving parts, inspecting for wear and tear, and cleaning the hoist regularly, you can prolong the hoist’s lifespan and prevent accidents in the workplace. Additionally, having the hoist serviced by qualified technicians at least once a year will help ensure its proper functioning and compliance with safety standards. Remember, a well-maintained hoist is a safe hoist.